Four top quality PTFE-based

material for every application.

KLINGERtop-chem:

A complete sealing package

for safe performance

THE LEADER IN GASKET TECHNOLOGY FOR MORE THAN 100 YEARS

| KLINGERtop-chem offer the advantages of PTFE

gaskets without the disadvantages commonly associated with PTFE materials.

This allows you to use these materials in applications where traditionally

they are unsuitable, saving you maintenance time and improving plant safety.

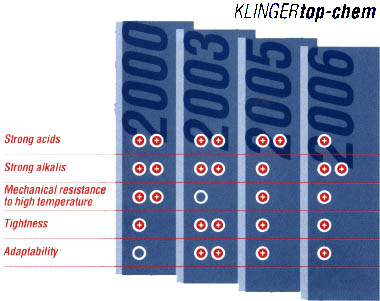

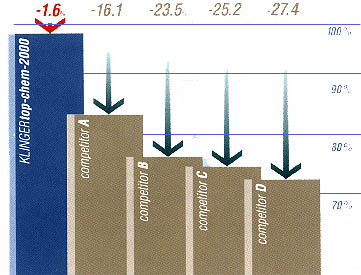

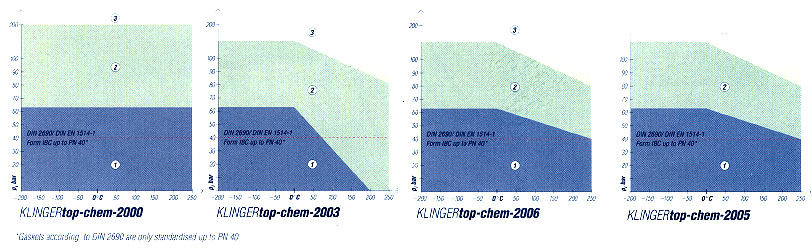

As an example, a comparison of the load bearing performance of KllNGERtop-chem-2000 with that of rival products is shown in the diagram below. With K1INGERtop- chem-2000, the high relaxation typical of standard PTFE gaskets is not observed. The results demonstrate that at a load of 50 I1IPa and temperature of 200"C, the relaxation of this material is only 1.6%, ensuring that bolt forces are maintained even under severe conditions. The two new grades KLINGER top-chem-2005 and -2006 offer a more economical solution for standard applications. They differ in respect to their chemical resistance. KLINGERtop-chem-2005 is particularly suited to strongly acidic applications while KLINGERtop-chem-2006 is the better choice for strongly alkaline conditions. By way of an introduction to the properties of the KLINGERtop-chem range, the matrix on the following page presents the attributes of the individual grades. The table illustrates that for all PTFE applications a suitable material can be selected from the KLINGERtop-chem range. The detailed performance data on the following pages will help you to choose the correct material for your application, ensuring the safe I performance of the gasket. The following short description of the four grades provides a general overview of properties and is the first step . towards making this choice. KLINGERtop-chem-2000 The universal heavy-duty gasket for an extremely wide

range of applications in the chemical and petrochemical industries as well

as in the ship building industry for chemical tanker applications. Due

to its unique load bearing properties it is able to withstand high temperatures

and pressures and it is the only PTFE gasket with a Fire Safe Certificate.

It is also the first choice in the food sector and in the pharmaceutical

industry far steam applications and in oxygen pipes, and where special

requirements are made ace. to TA Luft (German Clean air regulation)

|

|

|

KLINGERtop-chem-2003

As regards media, the range of applications is comparable

to that of KLINGERtop-chem-2000. However KLINGERtop-chem 2003 has greater

compressibility and is ideal for maintaining a tight seal even at low surface

loads and temperatures.

KLINGERtop-chem-2005 KLINGERtop-chem-2005 has excellent chemical resistance

in strongly acidic applications and good mechanical properties at medium

and low temperatures and loads.

KLINGERtop-chem-2006 KLINGERtop-chem-2006 has good chemical resistance in strongly

alkaline conditions and good mechanical properties at medium and low temperatures

and loads.

|

Stability according to Klinger

The load bearing capacity of a gasket can be assessed at ambient and high temperature using the hot compression test developed by Klinger.

In contrast to the test method according to DIN 52913 and BS 7531. The gasket stress is kept constant throughout the entire test. The gasket is thus exposed to significantly severer conditions.

The thickness decrease as a result of a constant load is measured at a temperature of 23'C and also after heating up to 250°C

The value of the thickness decrease at 250°C relates to the thickness after compression at 23°C.

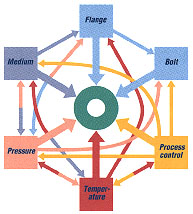

The Complex Demands on a Gasket

The successful operation of a gasketed joint depends on many parameters. Many users believe the suitability of a gasket for a given application can be defined on the basis of maximum temperature and pressure values, understanding that these are inherent material characteristics.

Unfortunately this is not the case: Maximum temperature and pressure values in isolation cannot define a material's suitability for an application since these limits are dependant upon a number of factors.

| KLINGERtop-chem | 2000 | 2003 | 2005 | 2006 |

| Ref.thickness of measured values,mm | 1.5 | 2 | 1.5 | 1.5 |

| Density,g/cm³ | 2.5 | 1.7 | 2 | 2.9 |

| Compressibility ASTM F 36A,% | 2 | 18 | 7 | 4 |

| Recovery ASTM F 36A,% | 55 | 40 | 35 | 40 |

| Stress relaxation | ||||

| DIN 52913, 16h, 50MPa, 300°c | 35 | - | - | - |

| DIN 52913, 16h, 30MPa, 150°c | 30 | 13 | 25 | 18 |

| Klinger cold/hot compression | ||||

| 23°c/50MPa,% | 2 | - | 10 | 10 |

| 250°c/50MPa,% | 5 | - | 30 | 40 |

| 23°c/25MPa,% | - | 9 | - | - |

| 250°c/25MPa,% | - | 38 | - | - |

| Sealability | ||||

| DIN 3535/6, ml/min | 0.5 | 0.1 | 0.2 | 0.1 |

| DIN 28090-2, mg/s m | 0.05 | 0.01 | 0.02 | 0.01 |

| Thickness/weight increase | ||||

| 0.5/1 | -/1 | 2/2 | - | |

|

|

1/2 | -/5 | 2/7 | 2/7 |

| NaOH, 33%,72h/110°c, % | 5/5 | -/2 | - | 12/24 |

| Permits/certifications | ||||

| BAM certification | yes | u. preparation | u. preparation | u. preparation |

| KTW proposal | yes | yes | u. preparation | u. preparation |

| DIN-DVGW permit | yes | yes | u. preparation | u. preparation |

| Fire Safe | yes | - | - | - |

| FDA Conformity | yes | yes | yes | yes |

| TA-Luft certification | yes | yes | - | - |

| Germanischer Lloyd | yes | yes | u. preparation | u. preparation |

| United States Cost Guard | yes | - | - | - |

| Registro Italiano Navale | yes |

- |

- | - |

| Det Norske Veritas AS | yes | - | - | - |

| Standared Sizes (other sizes on request) | ||||

| Sheet sizes mm | 1400/1400 | 1300/1300 | 1400/1400 | 1300/1400 |

| Thickness mm | 1.5/2.0/3.0 | 1.5/2.0/3.0 | 1.5/2.0/3.0 | 1.5/2.0/3.0 |

| Tolerances | thickness ± 10%, length ± 50mm, width ± 50mm | |||

Typical Values

Technical Modifications reserved, as at 07/98