English Supplement for KVN Pumps:

|

|

The piston valve

principle was a KLINGER idea. One of many ideas which have achieved

world-wide recognition. Continuously modified and matched to modern

requirements, the piston valve has proved itself by the million throughout

the world. Today we can say with pride that we are the world’s largest

manufacturer of valves based on this design principle. The sealing system is

astonishingly simple and extraordinarily effective: |

|

|

Always leak-tight across the

ports and to atmosphere |

The shut-off assembly

comprises a stainless steel piston, two resilient valve rings and a

ferrous-metal lantern bush. The sealing surface consists of the outer

vertical surface of the piston and the corresponding inner surfaces of the

sealing rings. This provides a very large sealing surface compared with globe

valves of conventional design- one of the reasons for the piston valve’s

excellent seal. |

|

|

Maintenance free |

The upper valve ring is

of KFK (Kor-P/KLINGERFLON®/Kor-P) and provides a reliable seal to atmosphere.

The middle layer of the ring is of KLINGERFLON (PTFE) and is fully contained

between Kor-P laminates, the valve body and the piston, in both the open and

shut positions. The pressure on the valve rings is provided by the nuts

securing the bonnet to the valve body. Belleville washers are fitted under

the bonnet nuts to ensure that the pressure of the bonnet on the valve rings

is kept constant this

maintains uniform contact of the PTFE with the piston and the body:

permeability to gases is reduced to a minimum and an optimum seal to

atmosphere guaranteed. The lower valve ring provides the seal across the

ports. The lantern bush serves as a distance piece between the two rings. The thrust produced by tightening the bonnet nuts acts axially from above; this thrust is transmitted from the upper valve ring, via the lantern bush, to the lower valve ring, which is contained in the body. The resilient sealing rings are thereby compressed and transform this thrust into a radially-acting pressure. Being supported against the wall of the valve body, the laminates of the valve rings are compressed around the piston and thereby produce an outstanding seal. |

|

|

Compensation for thermal

expansions |

KVN valves are fitted with Belleville washers as standard in conjunction with the resilient sealing rings this produces a spring-action sealing system. Owing to the different coefficients of thermal expansion of the various valve components, fluctuations of pressure and temperature create thermal expansions which inevitably lead to leakage. The Belleville washers, however, maintain constant pressure on the resilient valve rings and automatically compensate for any thermal expansions that may occur. The KVN valve stays tight - without maintenance. |

|

|

Unaffected by foreign matter

in the medium |

Foreign

matter in the medium can hardly harm a piston valve. When the valve is being

shut and the piston enters the lower valve ring, it automatically sweeps out

any particles of sand, welding globules or other impurities present in the

medium. The possibility of damage to the sealing system through abrasive

matter suspended in the medium

a well-known problem with conventional globe valves can effectively be ignored with

piston valves. Fibrous and contaminated media can be reliably shut off

without trouble. |

|

|

Environmentally acceptable +

energy saving |

The outstandingly good seal offers two advantages which should not be overlooked; there is no loss of medium (cost factor); and toxic or aggressive media cannot endanger the environment since they remain in the piping system. For KVN valves are leak-tight - both across the ports and to atmosphere. |

|

|

|

|

|

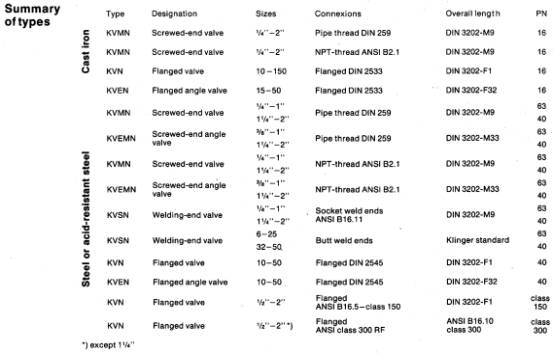

KVN 10-50,VIII cast steel |

|

KVN 65-200,VIII cast steel |

|

|

|

|

|

KVN 65-150, III cast iron |

|

KVN 10-50, Xc stainless steel |

|

|

|

|

|

KVMN 1/2”-2”, III cast iron |

|

KVN ANSI, VIII cast steel |

|

No erosion of the sealing surfaces |

The sealing

surfaces, i. e. the vertical surface of the piston and the inner surface of

the valve rings, lie outside the medium flow. Only the bottom of the piston

is directly exposed to the flow of the medium. Erosion of the sealing

surfaces and consequent leakage therefore cannot occur. |

|

Good regulating properties |

Thanks to

their design, KVN valves are as a general principle highly suitable for

throttling the medium flow without the need for special internals. If exact

regulation is required every standard valve can be converted to a regulating

valve simply by replacing the piston or lantern bush. Naturally the valve

body remains in the line during this procedure. |

|

Automatic actuators |

KVN

valves in all sizes may be provided with pneumatic, hydraulic or electro-

mechanical actuators from our KLINGERMATIC® range. For further

technical information please consult the relevant pages of our catalogues. |

![]()

|

|

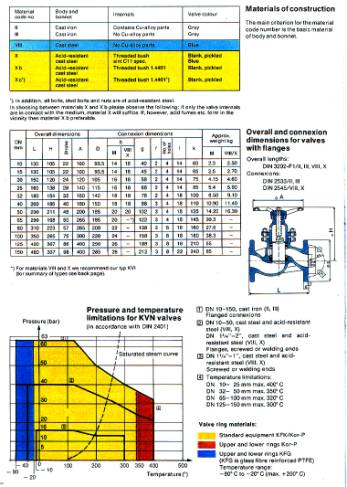

The valve rings are the

heart of a piston valve. They are made from Kor-P, a material specially

developed and exclusively used for the manufacture of valve rings. Kor-P

consists essentially of asbestos, a high quality elastomer and graphite. KLINGER valve rings are

not merely surface-graphited: the graphite content extends throughout the

ring. For this reason its outstanding self-lubricating properties are

retained throughout the ring’s entire

service life. Standard equipment KFK

ring/Kor-P ring covers the temperature range from-40°to+ 340°C. For

temperatures up to 400°C a Kor-P ring is also used as upper valve ring. For

exact areas of application please see the pressure/temperature diagram shown

in this folder. KLINGER Kor-P and KFK

valve rings are resistant to water, steam, oils, solvents and a wide variety

of other media (see KLINGER table of chemical resistance). Standard equipment

for the upper ring is always a KFK ring, the lower ring always Kor-P. (It

should be ensured that this arrangement is always adhered to, for example

when rings are being replaced.) We offer specially

developed materials for special applications such as strong inorganic acids,

foodstuffs and heat transfer oils (see our catalogue ”KLINGER Piston Valves” 7/81 E). KLINGER valve rings are

resilient, accurately dimensioned and, in consequence of their good recovery

characteristics, have excellent form retention and a long service life. |

![]()

|

|

Retightening - Servicing Fundamentially, the installation

of Belleville washers ensures that the valve will be kept leak-tight without

maintenance during service. However, we recommend that when KVN valves are

first taken into service the bonnet nuts should be re-tightened. This should

be done within one hour of the valve’s reaching its working temperature and

with the valve in the shut position. This simple

commissioning procedure guarantees the valve a long service life and

outstanding leak-tightness. If, after years of service, a valve develops a

leak which can no longer be put right by re-tightening the bonnet nuts (with

the valve shut), the valve rings should be replaced in accordance with our

maintenance instructions. No special equipment or skilled personnel is

required. Every semi-skilled labourer can replace the rings without trouble.

To help in installation we offer a kit of simple tools: a ring extractor, a

lantern bush extractor and a wooden drift. When the valve rings

have been replaced, a KVN valve is virtually as good as new. |

![]()

For sizes

65-200 in steel and acid-resistant steel we offer our KVI range. For higher

differential pressures and also for throttling or start-up conditions we

recommend the KVD series in sizes 65 to 200mm, materials VII, VIII. On request

we shall be glad to send leaflets and detailed documentation. Our catalogue KV 7.1/81E offers

comprehensive information on our entire valve programme.

~~The End~~